Introduction

Tapping

- Commodity name: Tapping

Product details

The double-head tapping machine is a highly efficient and precise thread processing device that can simultaneously tap both ends of a workpiece, significantly improving production efficiency. This equipment is widely used in industries such as machinery manufacturing, automotive parts, and hardware, and is particularly well-suited for high-volume, high-precision thread processing.

Core Features

1. Dual-Head Synchronous Processing: Taps both ends simultaneously, increasing efficiency by over 50% compared to single-head equipment.

2. High-Precision Control: Driven by a servo motor and equipped with a precision guide mechanism, thread accuracy can reach ISO Class 6H.

3. Automation Integration: Optional automatic feeding, clamping, and inspection devices are available, enabling fully unmanned production.

4. Versatile Adaptability: By replacing the tap chuck, it can process metric and imperial threads from M3 to M24, adapting to various materials (steel, aluminum, copper, etc.).

Typical Application Scenarios

- **Volume Parts**: Double-end threading of bolts, studs, pipe fittings, etc.

- **Automotive Industry**: Precision components such as engine connecting rods and drive shafts

- **Hardware Manufacturing**: Plumbing fittings and valve accessories

Double-end tapping machines, with their high efficiency, stability, and energy efficiency, have become core equipment for modern thread processing, particularly suitable for integration into automated production lines.

Keyword:

Video

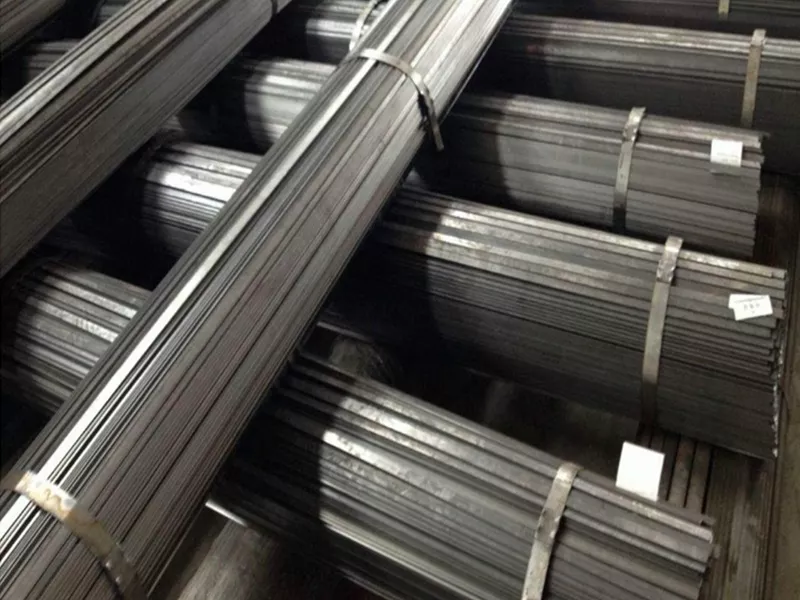

We have achieved high efficiency production through excellent understanding of the mechanical properties of various materials and advanced drawing equipment.

Packing & Shipping

Professional packaging and transportation solution - Safe, Efficient, End-to End Protection.

Leave a Message

Welcome your message consultation

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related products