Product details

Circular saws are efficient and precise metal cutting equipment widely used for cutting materials such as steel, aluminum, and pipes. They operate by cold-cutting materials with a high-speed rotating carbide saw blade or a high-speed steel saw blade. They deliver smooth cuts, precise dimensions, and high efficiency.

Process Advantages

1. High Precision: Utilizing a servo feed system, cutting tolerances can be controlled to within ±0.1mm, making them suitable for precision cutting.

2. High Efficiency: A high degree of automation allows for continuous cutting, significantly improving production efficiency.

3. Excellent Cut Quality: Burr-free and deformation-free, reducing subsequent processing steps.

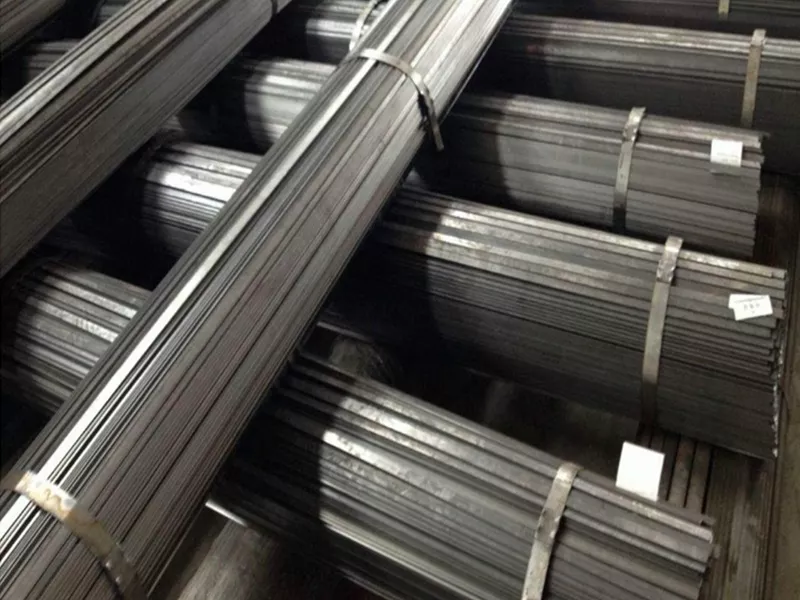

4. Wide Applicability: Capable of cutting a variety of profiles, including round steel, square steel, H-beams, and steel pipes, with a maximum cutting diameter exceeding 600mm.

Typical Applications

- Steel Structures: Beams, columns, and support blanking

- Mechanical Manufacturing: Shaft and flange blank cutting

- Pipeline Engineering: Cutting seamless and welded pipes to length

Circular saw blanking machines are particularly well-suited for high-volume, high-precision modern production. Combined with CNC control systems, they can also enable intelligent production management, making them essential process equipment in the metalworking industry.

Keyword:

Video

We have achieved high efficiency production through excellent understanding of the mechanical properties of various materials and advanced drawing equipment.

Packing & Shipping

Professional packaging and transportation solution - Safe, Efficient, End-to End Protection.

Leave a Message

Welcome your message consultation

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related products