Introduction

Galvanizing

- Commodity name: Galvanizing

Product details

Galvanizing is the process of coating metal surfaces (primarily steel) with zinc to prevent corrosion and extend their service life. Zinc's chemically active properties preferentially react with oxygen and moisture to form a dense protective film (such as basic zinc carbonate), insulating the steel from corrosive media. Even if the coating is partially damaged, the zinc can still provide sacrificial anodic protection, slowing down corrosion.

Main Galvanizing Methods: Hot-Dip Galvanizing

Immersing steel parts in molten zinc (approximately 450°C) creates a thick zinc-iron alloy layer (50-150μm). This layer offers excellent corrosion resistance and is suitable for steel structures, transmission towers, pipelines, and other applications.

Electrogalvanizing

A pure zinc layer (5-30μm) is deposited on the surface of the workpiece through electrolysis, resulting in a uniform and fine appearance. It is commonly used in automotive parts, fasteners, electronic components, and other applications.

Mechanical galvanizing

Zinc powder is applied to the workpiece surface through mechanical impact at room temperature. This method eliminates the risk of hydrogen embrittlement and is suitable for batch processing of small parts.

Cold galvanizing (zinc-based coating)

Zinc-based coatings are applied by spray or brush as a repair or supplemental protective method.

Galvanizing offers low cost and excellent protection, making it a cornerstone of industrial rust prevention.

Keyword:

Video

We have achieved high efficiency production through excellent understanding of the mechanical properties of various materials and advanced drawing equipment.

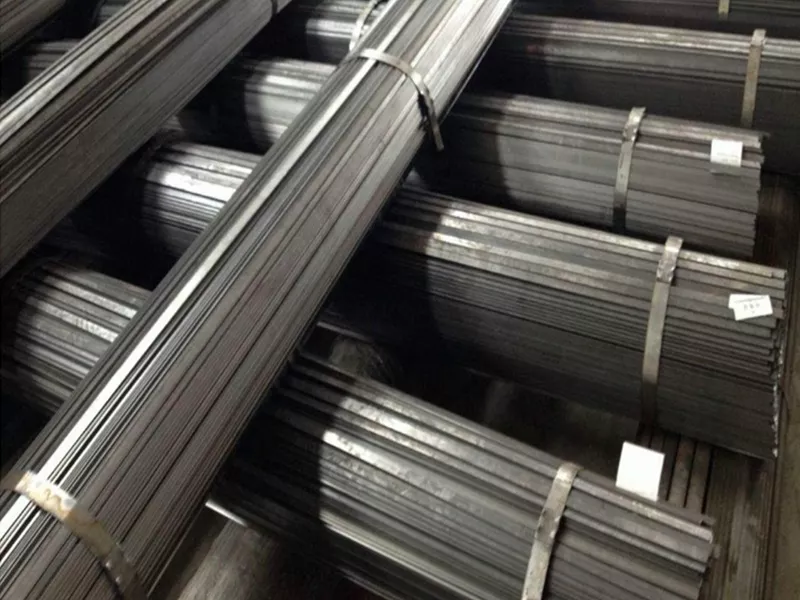

Packing & Shipping

Professional packaging and transportation solution - Safe, Efficient, End-to End Protection.

Leave a Message

Welcome your message consultation

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related products